Nanjing Kisen independently developed third generation aeration beam grate cooler, KS high efficiency low resistance five stage cyclone preheater and multi spouting calciner, double swirl multi-channel pulverized coal burner, KGP clinker roller crusher, NTC cement kiln humidification spray system, PF2020 impact crusher, cement external circulation vertical mill, fourth generation row forward cooler with middle roller crusher, raw material roller press, double string preheater with single calciner for 10000t/d line, large-scale cement pipe mill system and other products have passed the certification of Jiangsu Province's high-tech products and the appraisal of the Ministry of Science and Technology of China Building Materials Federation.

Nanjing Kisen low energy consumption clinker burning technology has achieved a new breakthrough in the industry. In recent years, Nanjing Kisen has developed high efficiency and low resistance six-stage preheater, high efficiency and low nitrogen calciner, fourth generation row forward cooler with middle roller crusher, high thrust and low primary air efficient burner, two-support low energy consumption short kiln and other low energy consumption clinker burning technology and equipment. Among them, the resistance of the six-stage preheater is lower than that of the five-stage preheater in China in 2010. The exit temperature of C1 is lower than 260℃, which effectively reduces the coal consumption by more than 5kg standard coal/t.cl. The fourth generation row forward cooler with middle roller crusher effectively improves secondary air temperature, tertiary air temperature and waste heat power generation. The secondary air temperature can reach more than 1200℃, which reduces clinker temperature and system coal consumption. CUCC Taian 5000 tpd low energy consumption demonstration line, which was generally contracted by Nanjing Kisen, was put into operation in 2015. The burning system of the demonstration line adopts Nanjing Kisen's proprietary technology. The heat consumption of the burning system is 94 kg standard coal/t-cl, and the comprehensive power consumption of clinker is less than 46 kWh/t-cl.

Nanjing Kisen has developed cement external circulation vertical mill combined grinding, semi-final grinding and final grinding system with independent intellectual property rights. Among them, more than 20 patents have been granted to the external circulation vertical grinding equipment, core components and three kinds of external circulation grinding process systems, which pioneered the external circulation vertical grinding technology of cement at home and abroad. The final grinding system of cement external circulation vertical mill has been successfully applied in CUCC Lunan Project. The power consumption of the grinding system is less than 26 kWh/t, which is 2-4 kWh/t lower than that of the internal circulation vertical mill system. Up to now, more than 10 cement vertical mills have been put into industrial application. Ball mill system has been reformed by combined external vertical mill or semi-final grinding system. The output of cement can be increased by 1-2 times and the power consumption can be reduced by more than 10 kWh/t. Cement external circulation vertical grinding technology and equipment won the first prize of technological innovation and technological research and development in the national building materials industry in 2014 "Keda Cup". Cement external circulation vertical grinding system won the first prize of technological innovation and technological research and development in the national building materials industry in 2017 "Jida Cup". Cement external circulation vertical grinding technology and equipment won the 2009 China Building Material Federation "Two Second Generation" technology and equipment innovation promotion research and development outstanding research and development achievements award.

Nanjing Kisen integrates innovative development of high efficiency roller press and final grinding system. The independently developed raw material roller press is applied to Longshan Project in Xuzhou. The technical index of the raw material grinding system exceeds the other two domestic brand roller press systems of the plant. The integrated and developed high-efficiency roller press cement combined grinding process system is applied to Southern Cement Haiyan Project. The power consumption of cement is less than 24kWh/t, which has reached the international leading level.

Project Achievements

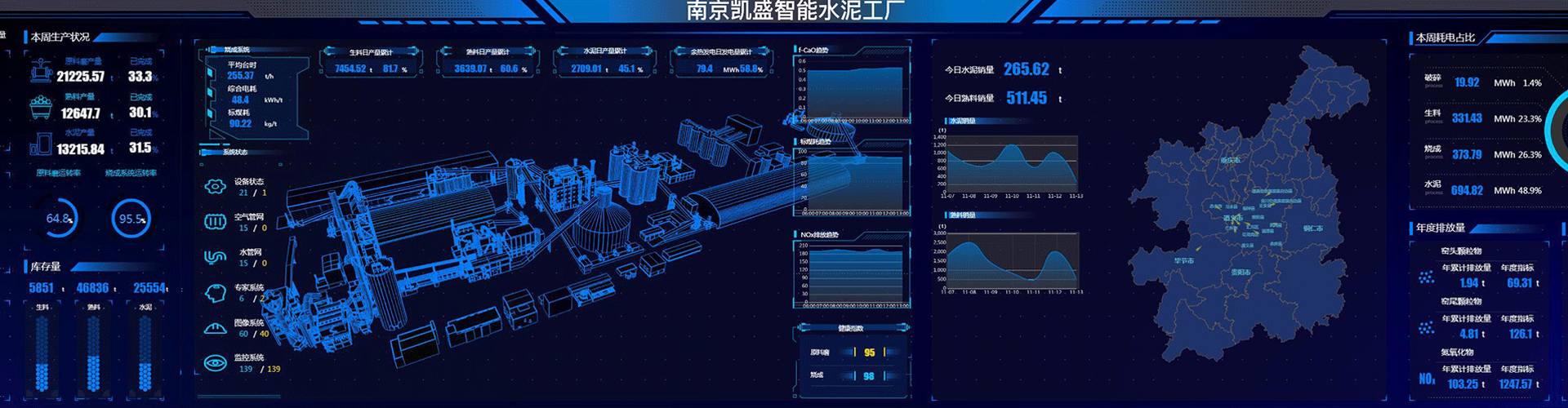

The R&D and implementation of Nanjing Kisen intelligent plant is in the leading position in the industry. Since 2012, combined with the company's rich experience in cement design, plant construction, commissioning and cooperation with foreign large automation enterprises for many years, a lot of research and development work has been done on intelligent manufacturing solutions for cement industry. In 2014, the Intelligent Manufacturing Division was set up to establish solution research and design, product design, algorithm development, software development, testing, market management, project management, system implementation team, operation and maintenance support teams, and obtained CMMI3 (Capability Maturity Model Integration, i.e. software capability maturity integration model level three) certification. After a lot of research and repeated exploration, the R&D team has established data model and business model in line with the cement industry, and developed an intelligent plant operation and maintenance management platform with independent intellectual property rights, which is more suitable for cement process enterprises, and an expert intelligent control system of Nanjing Kisen. In 2015, CUCC Taian 5000t/d new dry process cement production line project, which was generally contracted by Nanjing Kisen, was selected as the only project of cement industry as one of 46 intelligent manufacturing demonstration projects of Ministry of Industry and Information Technology in 2015. Its intelligent manufacturing platform adopted Nanjing Kisen Intelligent Plant Operation and Maintenance Management Platform V1.0 and Nanjing Kisen Expert Intelligent Control System V1.0. At present, Nanjing Kisen Intelligent Manufacturing Solution and Software Platform has iterated to V3.0 version, and has been put into use in more than 20 production lines, such as CUCC Taian, Southern Cement Haiyan, Zunyi Saide, Sampyo Cement, CUCC Pingyi, etc., with good results, which has played an active role in saving energy, reducing consumption and increasing efficiency, reducing labor intensity of workers, and protecting environment, and has realized the life cycle service of intelligent cement plant from design, construction to operation and maintenance.