Research Power

Nanjing Kisen has a professional, skilled, innovative and team spirit R&D team. There are more than 100 full-time technical developers in the company. Among them, there are more than 30 professor-level senior engineers, more than 90 senior engineers, more than 60 PhDs and masters. Under the strong support of China National Building Materials Group Corporation Technology Center, they carry out independent innovation work.

For years, Nanjing Kisen insisted the development pattern of combination of production, study and research. It cooperated with research institutes such as Tongji University, Southeast University, Nanjing University of Technology, Nanjing University of Aeronautics and Astronautics, and domestic and international famous enterprises such as Japan Mitsubishi, Denmark FLSmidth etc. Through internal technology innovation and external cooperation, Nanjing Kisen has accomplished all kinds of cement burning systems with self-owned intellectual property rights. Among them, the burning system of CUCC Tai’an 5000t/d production line, CUCC Xuzhou 10000t/d 2nd production line, Turkey Akcansa 6000t/d production line with high sulfur petroleum coke as fuel, Saudi Al-Jouf 5000t/d production line with heavy oil as fuel, Luojiang Lisen 2500t/d production line with partial limestone replacement from carbide slag, Southern Cement Shanggao 5000t/d production line with 100% anthracite as fuel are all independently developed by Nanjing Kisen and the indexes of the systems have reached the leading level in China and the advanced level in the world.

For years, Nanjing Kisen insisted the development pattern of combination of production, study and research. It cooperated with research institutes such as Tongji University, Southeast University, Nanjing University of Technology, Nanjing University of Aeronautics and Astronautics, and domestic and international famous enterprises such as Japan Mitsubishi, Denmark FLSmidth etc. Through internal technology innovation and external cooperation, Nanjing Kisen has accomplished all kinds of cement burning systems with self-owned intellectual property rights. Among them, the burning system of CUCC Tai’an 5000t/d production line, CUCC Xuzhou 10000t/d 2nd production line, Turkey Akcansa 6000t/d production line with high sulfur petroleum coke as fuel, Saudi Al-Jouf 5000t/d production line with heavy oil as fuel, Luojiang Lisen 2500t/d production line with partial limestone replacement from carbide slag, Southern Cement Shanggao 5000t/d production line with 100% anthracite as fuel are all independently developed by Nanjing Kisen and the indexes of the systems have reached the leading level in China and the advanced level in the world.

Over the past five years, Nanjing Kisen has been following the trend of green intelligent manufacturing and energy saving and emission reduction in cement industry, actively responding to the research and development requirements of the "Two Second Generation" of China Building Materials Federation on "Second Generation of New Dry-process Cement", transcending the first generation of new dry-process cement from the aspects of technology, equipment, control technology, technical and economic indicators, etc. Independently developed low energy consumption clinker burning technology, high efficiency grinding technology, high efficiency and low discharge intelligent environmental protection technology, waste disposal and utilization technology, intelligent technology of cement industry have been successfully applied to more than 100 domestic production lines, some of which have achieved new breakthroughs in the industry and made up for the industry gap.

Over the years, Nanjing Kisen is committed to research, develop and promote the energy saving technology and equipment with nearly 200 patents. KS type high efficiency and low resistance five-stage cyclone preheater and multi-spouting calciner, third generation aeration beam grate cooler, high efficiency reciprocating grate cooler, dual swirl multi-channel pulverized coal burner, KGP type clinker roller crusher, NTC type cement kiln conditioning tower spraying system, PF2020 type impact crusher, cement external circulation vertical mill, row-forward cooler with middle roller, raw material roller press, double string preheater with single calciner for 10000t/d line and large-scale cement pipe mill system have passed the certification of high-tech products in Jiangsu Province. Gear roller clay crusher, KVM-P series pre-grinding vertical mill, KSRP raw material roller press, KGP high temperature clinker roller crusher, KC4 new high efficiency grate cooler, low NOx combustion and flue gas denitrification technology have been put into use in more than 100 cement production lines. More than 20 invention patents have been granted to the external circulation vertical grinding equipment and core components and three kinds of external circulation grinding process systems. Up to now, cement external circulation vertical mill has been put into industrial application in more than 10 sets.

Nanjing Kisen has its own characteristics in the use of cement kiln cooperative disposal and ultra-low emission technology. Among them, the first generation of SNCR denitrification technology is applied to more than 100 production lines, and some production lines are equipped with expert optimization control system. Since the wet desulfurization technology was put into use in Southern Cement Leiyang Project, the SO2 emission concentration has dropped from 2000 mg/Nm3 to about 50 mg/Nm3. The project of synergistic disposal of waste by cement kiln in Qianxi Southwestern Cement in Guizhou, the project of synergistic disposal of sludge of Hejiashan cement kiln in Zhejiang and the project of co-production of activated desulfurized manganese slag with manganese slag in Tianyuan manganese industry in Ningxia have been put into use.

Nanjing Kisen pays great attention to study low-grade raw materials such as low calcium, high sulfur, high magnesium, high alkali, high chloride etc. Moreover, Nanjing Kisen also studies plaster sulfate cement technology and carbide slag, iron slag, phosphorus slag and other industrial waste for their utilizations in cement production. In our design of Zhejiang Hejiashan 2500t/d cement production line, the proportion of use of industrial solid waste in the cement raw fuel, additive and retarders accounts for 47%. This project won 2006 National Excellent Engineering Design Bronze Medal.

In addition, we also have put great efforts to develop industrial and prospective energy saving and emission reduction technologies, such as oxygen-rich calcination technology, CO2 emission reduction capture and re-use technology, SO2 emission control technology, PM2.5 control emission technology etc. Now we have made a breakthrough progress.

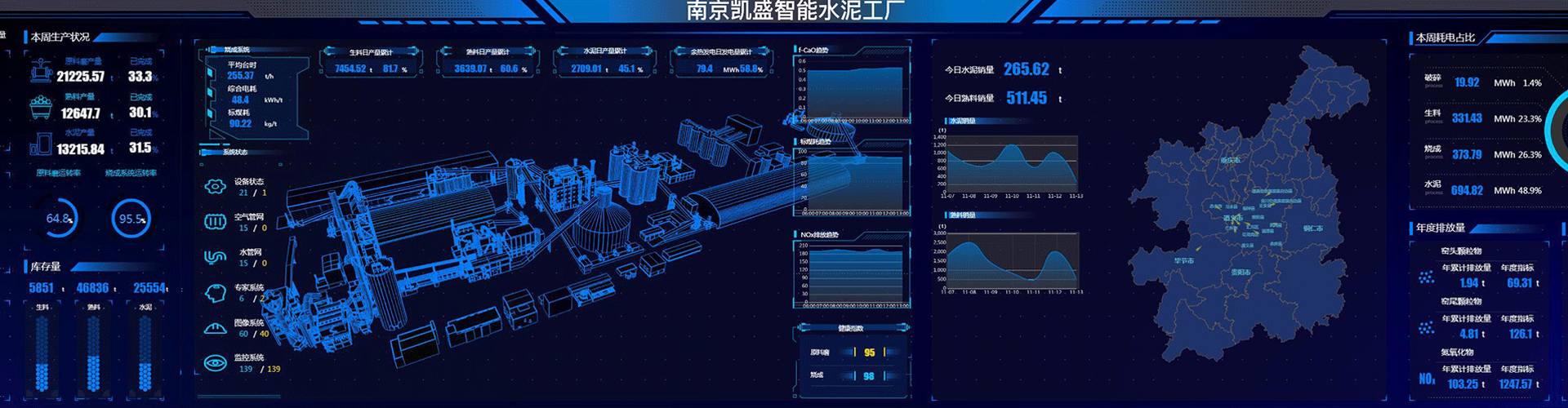

Under the background of Industry 4.0, supported by the Civil, Process, Electrical Automation Research Institute and the Technical Center Team of the former design institute, combining its rich experience in cement design, plant construction, commissioning and cooperation with large foreign automation enterprises, Nanjing Kisen set up an Intelligent Manufacturing Division in 2014. There are more than 50 staff for research and design, product design, algorithm development, software development, testing, market management, project management, system implementation team and operation and maintenance support team. 99% of them are college graduates or above. It has been certified by CMMI3 (Capability Maturity Model Integration, the third level of software capability maturity integration model). Aiming at the bottleneck technology of process, equipment, electricity and software, it designs a set of intellectualized solution for the plant, which fully fits the cement process industry. It also develops an intellectualized plant operation and maintenance management platform with independent intellectual property rights, which is more suitable for cement process enterprises, and an expert intelligent control system of Nanjing Kisen. The system has been put into use on more than 20 production lines such as CUCC Tai’an, Southern Cement Haiyan, Zunyi Saide, Sampyo Cement in Korea, CUCC Pingyi etc. The application effect is good, which plays a positive role in energy saving, labor intensity reduction and environmental protection of cement plants, and realizes the whole life cycle service from design, construction to operation and maintenance for an intellectualized cement plant.

With its powerful technical innovation strength, Nanjing Kisen insists the development pattern of combination of production, study and research and cooperation with domestic and international enterprises. By the chance of promotion energy saving and emission reduction of China, it will open more and more new technical innovation fields.