Nanjing Kaisheng Digital Intelligence Empowers Taian Zhonglian's New Development

Release Time:

2023-02-23 17:08

To continuously promote the high-quality development of the enterprise and achieve the goal of "digital + energy saving", Nanjing Kaisheng recently completed the upgrade and iteration of the first-generation smart factory of Taian Zhonglian Cement Co., Ltd.

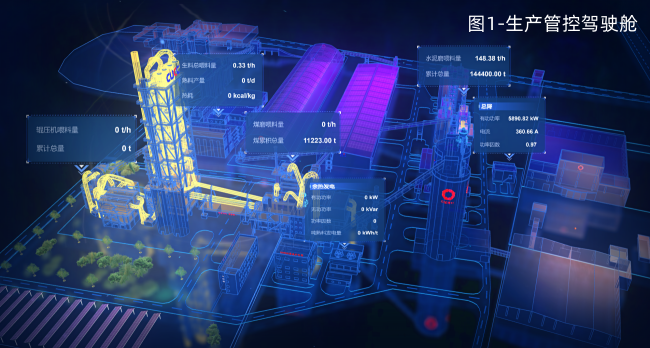

This smart factory upgrade project began in December 2021 and lasted for one year. Nanjing Kaisheng's intelligent manufacturing team, acting as the general contractor, adhered to the principles of "intensification, greening, intelligence, and high-end" to comprehensively build five major systems at Taian Zhonglian: a data center platform, a production control platform, an intelligent control system, a full-process quality control platform, and a 5G smart mine. This achieved full-link integration from raw materials entering the plant to finished products leaving the plant, helping the enterprise continuously deepen its "three-refinement" management and enhance its core competitiveness.

Taian Zhonglian's standardized data center platform integrates real-time production data, video surveillance data, intelligent equipment data, and supply and sales data. It refines and processes this data to achieve visual applications for data services, enabling employees to apply data more conveniently.

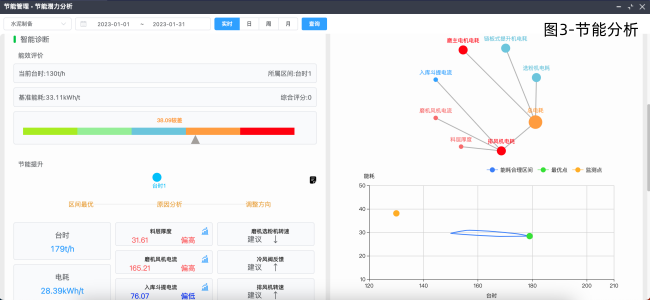

The production control platform serves as Taian Zhonglian's production management center. Among its features, the energy management system makes the production process transparent by real-time monitoring of production consumption data, promptly pushing abnormal data, and conducting traceability analysis. This assists production managers in formulating optimal production scheduling, energy consumption, and process operation plans, and quantitatively evaluating production process performance.

The equipment management system incorporates Taian Zhonglian's TPM management experience. Tasks such as equipment maintenance and troubleshooting, video inspections, and lubrication can be automatically processed through work orders, achieving closed-loop management. Concurrently, the online equipment diagnostic system and the equipment management system are integrated to share equipment status information, establishing a predictive maintenance process for the enterprise, effectively increasing equipment continuous operation rate, and ensuring stable production.

The intelligent control system is the production operation brain of Taian Zhonglian. Utilizing technologies such as edge computing, machine learning, and big data analysis, the intelligent control system possesses the ability to identify abnormal production conditions and autonomously optimize control. Concurrently, it integrates with quality prediction and "one-button start-stop" systems, transforming production operations from "manual control" to "intelligent driving". After the system was put into operation, its overall operational rate reached 98%, the abnormal condition recognition rate exceeded 90%, achieving intelligent control of kiln and mill systems.

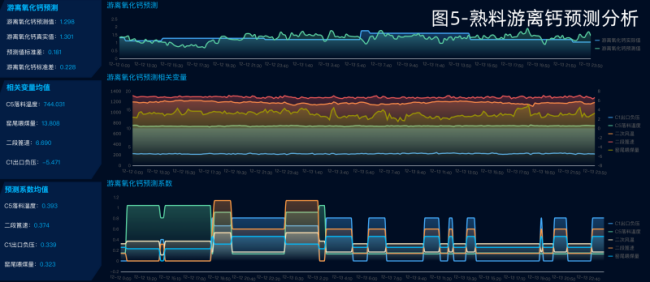

Leveraging online analysis and detection equipment, fully automated laboratories, and quality systems, Taian Zhonglian has largely achieved full-process quality control in production, forming a closed loop for quality management. Production process quality data is frequently detected, and data is automatically collected and analyzed. Additionally, algorithmic models have been established for raw meal closed-loop control optimization, clinker free lime prediction, and 28-day strength prediction for clinker and cement, leading to an approximate 10% increase in qualified raw meal quality and about a 12% increase in qualified clinker quality.

With the help of key technologies such as 5G, IoT, AI, big data, and cloud services, Taian Zhonglian's mining area intelligent dispatch platform comprehensively manages electric mining trucks, autonomous driving systems, and excavation-transport collaboration systems. This seamlessly connects the entire "loading, transportation, and unloading" process of complex production operations in the mining area, maximizing operational safety, reducing cost consumption, promoting economic and environmental benefits, and truly realizing the construction of a 5G smart mine.

Through this upgrade and transformation, Taian Zhonglian has significantly improved in data processing and application, making data a crucial production factor and driving the enterprise's transition towards digital management. Overall plant production efficiency increased by approximately 18%, coal consumption decreased by 1.5%, and electricity consumption decreased by 1.2%. Production data has become a valuable data asset for the enterprise, laying a solid foundation for its high-quality development.

During this upgrade and transformation, Nanjing Kaisheng's intelligent manufacturing team and Taian Zhonglian formed a joint intelligent group. Building upon the first-generation smart cement factory from 2016, they organically integrated new intelligent technologies with factory operations to create optimal application scenarios, comprehensively enhancing the enterprise's profitability and solidifying Taian Zhonglian's leading position in the industry. Concurrently, Nanjing Kaisheng and the enterprise collaborated for mutual benefit, establishing a joint talent training mechanism to assist Taian Zhonglian's digital transformation and the development of a digital talent pipeline. This helps the enterprise achieve intelligent and efficient management and control across the entire process of production operations and business management, potentially reducing production costs by over 8 million yuan annually, saving over 1000 tons of standard coal, and generating significant economic and social benefits.